|

| December 24, 2019 | Volume 15 Issue 49 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Good news for aero and medical: Adding copper strengthens 3D-printed titanium

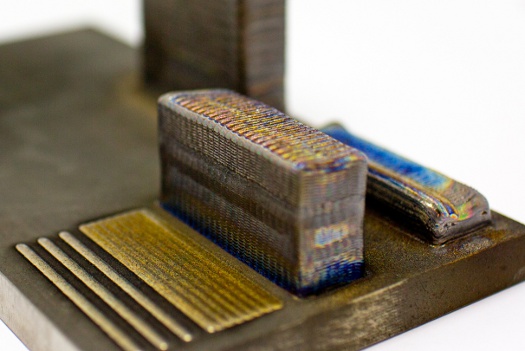

Titanium and copper powder with 3D-printed bars.

Successful trials of titanium-copper alloys for 3D printing could kickstart a new range of high-performance alloys for medical device and aerospace applications.

By Michael Quin, RMIT University

Current titanium alloys used in additive manufacturing often cool and bond together in column-shaped crystals during the 3D-printing process, making them prone to cracking or distortion.

And unlike aluminum or other commonly used metals, there is no commercial grain refiner for titanium that manufacturers can use to effectively refine the microstructure to avoid these issues.

But now a new titanium alloy with copper, unveiled Dec. 5 in Nature, appears to have solved this problem.

Professor Mark Easton from RMIT University's School of Engineering in Melbourne, Australia, said their titanium-copper alloy printed with "exceptional properties" without any special process control or additional treatment.

"Of particular note was its fully equiaxed grain structure. This means the crystal grains had grown equally in all directions to form a strong bond, instead of in columns, which can lead to weak points liable to cracking."

"Alloys with this microstructure can withstand much higher forces and will be much less likely to have defects, such as cracking or distortion, during manufacture," Easton said.

A 3D-printed titanium-copper block made at RMIT's Advanced Manufacturing Precinct.

The collaborative project brought together leading researchers in the area of alloy composition and grain microstructure from RMIT University, CSIRO, the University of Queensland, and the Ohio State University.

Dr. Mark Gibson, CSIRO senior principal research scientist, said their findings also suggest similar metal systems could be treated in the same way to improve their properties.

"Titanium-copper alloys are one option, particularly if the use of other additional alloying elements or heat treatments can be employed to improve the properties further," he said. "But there are also a number of other alloying elements that are likely to have similar effects. These could all have applications in the aerospace and biomedical industries."

Gibson said the new breed of alloys could increase manufacturers' production rates and allow for more complex parts to be manufactured.

"In general, it opens up the possibility of developing a new range of titanium-based alloys specifically developed for 3D printing with exceptional properties," he said.

The work was part of a project funded by the Australian Research Council.

Published December 2019

Rate this article

View our terms of use and privacy policy